Top-mounted dryers for plastic granules

JETBOXX®

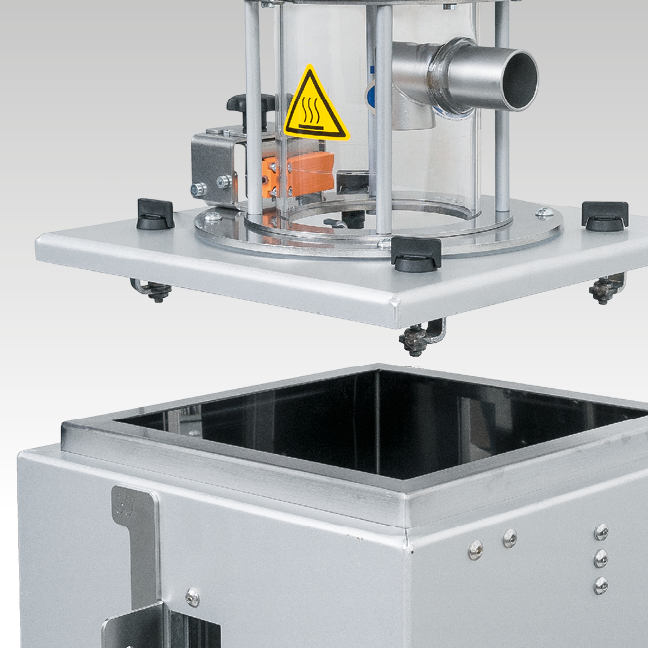

Dryers for direct mounting on the feeding zone

Mounting directly on the injection unit of the processing machine

The dryer is placed directly on the feeding zone of an injection moulding machine. As a result, the dried material flows directly from the dryer into the plasticising cylinder without re-moistening or cooling.

Sizes

WINneo®2 Mini

JETBOXX® Mini Set

3 liters

Example:

Manual filling

JETBOXX® Mini Set

6 liters

Example:

Conveyor Option C Mini

Material throughput:

up to 1,2 kg|h

JETBOXX® Mini Set

12 liters

Example:

Conveyor Option C Mini

Material throughput:

up to 2,4 kg|h

JETBOXX® Mini Set

24 liters

Example:

Conveyor Option C

Material throughput:

up to 4,8 kg|h

WINneo®2

JETBOXX® Set

20 liters

Example:

Conveyor Option C

Material throughput:

up to 4 kg|h

JETBOXX® Set

30 liters

Example:

Conveyor Option C

Material throughput:

4−6 kg|h

JETBOXX® Set

50 liters

Example:

Conveyor Option C

Material throughput:

6−10 kg|h

JETBOXX® Set

75 liters

Example:

Conveyor Option C

Material throughput:

10−15 kg|h

Drying containers

|

|

|

|

|

|

|

|

|

| 3 liters | 6 liters | 12 liters | 24 liters | 20 liters | 30 liters | 50 liters | 75 liters | |

| Weight [kg] | 6,7 | 9,0 | 12,0 | 14,0 | 15,5 | 19,0 | 25,3 | 35,3 |

| Height [mm] | 421 | 431 | 569 | 727 | 491 | 623 | 780 | 921 |

| Width [mm] | 314 liters | 314 | 358 | 335 | 413 | 413 | 420 | 433 |

| Depth [mm] * | 249 liters | 322 | 361 | 405 | 415 | 415 | 446 | 542 |

| Swivel lid | Swivel lid | Hinged lid | Hinged lid | Hinged lid | removable | removable | removable | removable + cleaning door |

| optional | Hinged lid | Hinged lid | Hinged lid | Hinged lid | ||||

| Filling volume max. | 3 liters | 6 liters | 12 liters | 24 liters | 20 liters | 30 liters | 50 liters | 75 liters |

| Probe- adjustment range |

2−5 liters | 4−10 liters | 6−20 liters | - | 20−26 liters | 30−45 liters | 50−70 liters |

* incl. WINneo® 2 control

Examples of use

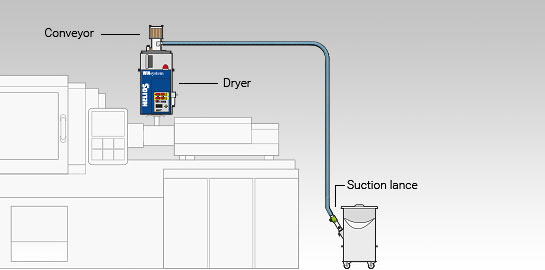

A variant

- The top-mounted dryer is installed directly on the feeding zone

- Conveying of one component with the integrated compressed air conveyor and suction lance

- Drying of granulate with parameters that are dependent on throughput and plastic specific

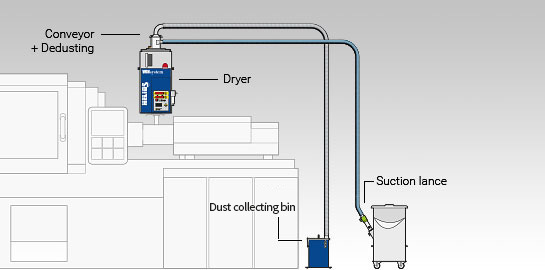

B variant

- The top-mounted dryer is installed directly on the feeding zone

- Conveying of one component with the integrated compressed air conveyor/deduster and suction lance (CE option)

- Dust removal by whirling up by means of compressed air jet after each conveying cycle. The separated dust is led into a dust collecting bin

- Drying of dedusted granulate with parameters that are dependent on throughput and plastic specific

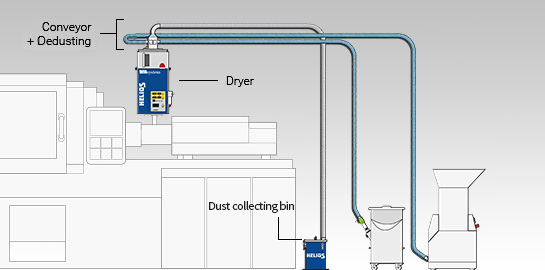

C variant

- The top-mounted dryer is installed directly on the feeding zone

- Conveying of two components (virgin material + regrind) with the integrated compressed air conveyor/deduster and two suction lances (ME option)

- Dust removal by whirling up by means of compressed air jet after each conveying cycle. The separated dust is led into a dust collecting bin

- Drying of dedusted granulate with parameters that are dependent on throughput and plastic specific

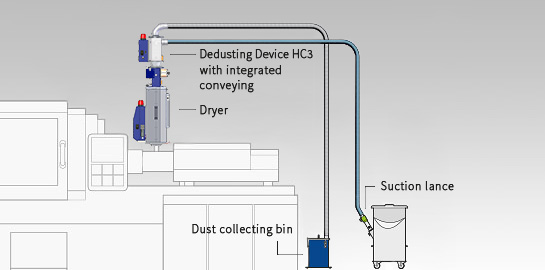

D variant

- The top-mounted dryer is installed directly on the feeding zone

- Conveying of one component with the integrated compressed air conveyor in the HC3 dedusting unit

- Dust removal by whirling up by means of compressed air jet after each conveying cycle. The separated dust is led into a dust collecting bin

- Drying of dedusted granulate with parameters that are dependent on throughput and plastic specific

Easy access. Easy to clean.

Hinged lid

The lid can be hinged with a handle.

Standard for 6|12|24 liters, optionally for 20|30|50|75 liters.

Removable lid

The lids are removable in standard by bayonet locks for 20 to 200 liters container sizes.

Remove air distributor

The special JETBOXX® air distributor pipe can be removed easily without any tools.

Cleaning from top

The JETBOXX® drying container can be opened easily from top for cleaning. The high quality inner wall made of stainless steel allows a 100 percent cleaning

Cleaning door

The drying containers with size 75 to 200 liters have a cleaning door at the rear. In that way, the cleaning also in these sizes can be done easily.

Variable filling level

| Container volume |

6 liters | 12 liters | 24 liters | 30 liters | 50 liters | 75 liters |

| Minimum filling level |

> 2 liters | > 4 liters | > 6 liters | > 20 liters | > 30 liters | > 50 liters |

Change of control unit without tools

WINneo® 2

The removable JETBOXX® control unit can be easily detached from the drying container.

On the WINneo® 2 (top image), this is done using 4 movable snap locks and on the WINneo® 2 Mini (belowe image) using a central clamping fastener.

This means that during maintenance work, such as calibration, an bridging control can be attached without interrupting production

JETBOXX® control range WINneo® 2

| WINneo®2 | ||

| Quick selection keys | Drying program / drying intensity |

|

| Filling level calculator |

|

|

| System settings |

|

|

| Weektimer |

|

|

| Conveying ON/OFF |

|

|

| Conveying points |

Conveying point 1 (drying container filling) - 1 Component with dedusting |

|

|

Conveying point 1 (drying container filling) - 2 Components with dedusting |

|

|

|

Conveying point 1 (drying container discharge aid) Discharge aid with air pulses |

|

|

|

Conveying point 2 (processing machine feeding) - 1 Component with dedusting |

|

|

| Functions | Dew point display with alarm function |

|

| Overdrying protection |

|

|

|

Limitation of the drying temperature with adjustable tolerance |

|

|

| Interfaces | Modbus RTU |

|

| TCP/IP |

|

|

| OPC-UA |

|

|

| NEW | Remote Control / WINneo®2 connect |

|

standard

|

||

optionally

|

||

Do you have any questions about us or our products?

Just send us a quick message and we’ll gladly get back to you via phone or mail to answer any open questions.

Customer support service by telephone

We will gladly answer all open questions.

or use your own e-mail program:

Privacy policyThe data sent will only be processed for the purpose of processing your request. You can find further information in our data protection declaration. |